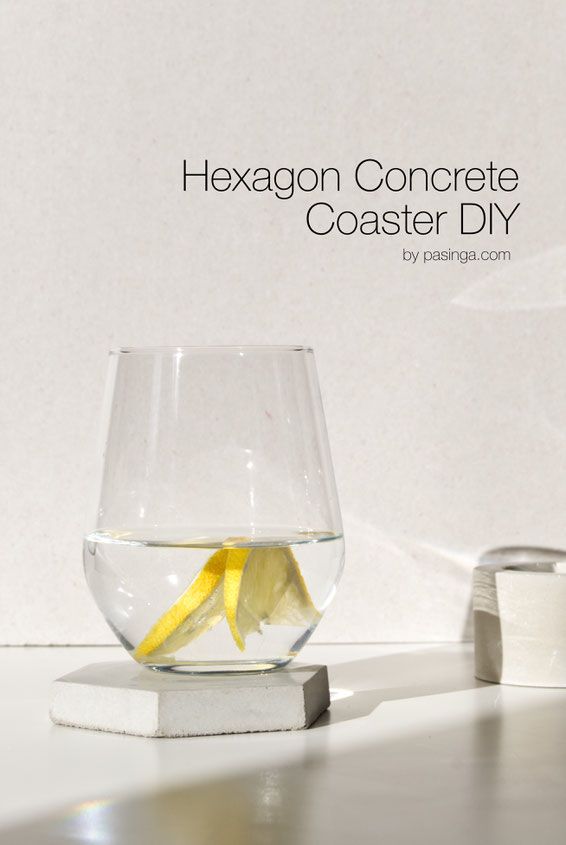

Spring is almost here and with it my desire to refresh and restyle my home. I hope I am not alone but I just fancy that fresh breeze, the soft spring sunshine and hope to catch it inside. I never really use coasters, no expensive furniture here, but my friend asked me about it and so did my mom and I just thought why not. I mean, they can be used in so many ways anyway, so here we go ... let us craft modern concrete hexagon coasters together!

Materials:

hexagon plastic moulds or a self build mould, fibre mat for reinforcing, concrete mix, mixing tools like plastic spoon and cups or containers and maybe sanding paper / sanding block, and for your safety - glasses, a mask and gloves

Workstation & Time:

It is best that things remain where they are poured for at least 2 to 3 hours for most fast setting mixes or 24 hours for a standard mix; it helps if the surface is flat and fairly straight; Minimum time required is 3 hours but you will have at least 2 hours of free time in-between

First things first - preparing the moulds and fibre mat ....

If you are using one of my recycled plastic moulds nothing needs to be done as they are so smooth they will finish nicely. If you are worried or have used the mould before and it is not new anymore, a quick wipe with a bit of veggie oil on a paper towel could be of help.

Should you have build your own hexagon mould, maybe with one of the up-cycled materials or the aluminium foil finish I have shown in earlier tutorials, make sure the surface for the vessel/glass to put on later is fairly even.

Let us move on to the re-inforcement for these coasters. It is not a must but if a major crack occurs or it has fallen of the table it wont fall into pieces, maybe it even adds a bit of character.

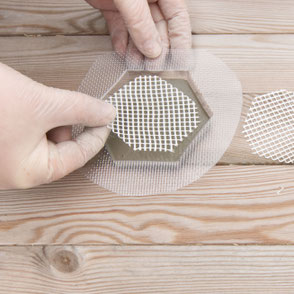

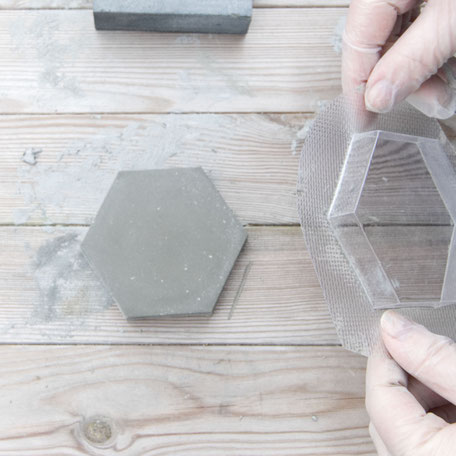

I recommend a matting for this project as it is easy to cut, often made of recycled materials and cleaner compared to loose fibres. You wont need more than an A4 sheet for 4 coasters if you use my mould. Cut the mat to a hexagon shape, almost the size of the mould [image below, left hand]. The left over corners, shown below right, are not waste they will be the second layer and also added later.

The Workstation - get your mixing tools, gear up with mask, glasses and gloves. Once done it is time for some water and your concrete and aggregate or a quick mix. I recommend a quick mix as it will only need some water and keeps the project time down. You can choose any mix available at your home or builders market. More on this can also be found in my previous DIYs.

Mix your concrete! Often you can use a 1:3 ratio, so one plastic cup water and 3 cups concrete mix. But as I said the mix will depend on the brand you are using. The ratio should be on your concrete mix as well and it is always good to check those instructions too.

Rule of thumb > your mix should be keeping the shape as indicated to the right and when you shape the whole mixture it will even out but only then. Even more details are here too!

Add about two spoons of concrete to your mould. I used a normal plastic spoon/soup spoon just to help with the ratio but it is supposed to form the first thin layer in the mould not more.

Shake the mould to release air bubbles and to have a thin layer of concrete all over the base of the mould which will be later the top of your coaster.

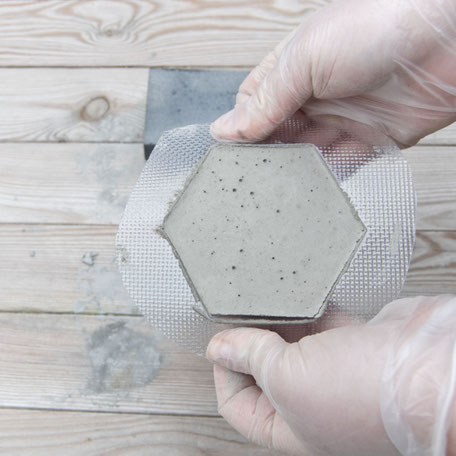

The Reinforcement

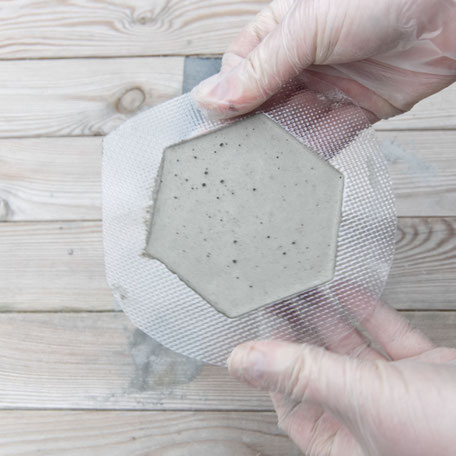

Once the base is covered add your hexagon shaped mat with only millimetres to spare to each side of the mould.

Push it into the concrete by tapping the mat all over the place.

Once it is fairly sunken in add another spoon of concrete to the centre of the mat.

No shaking this time. Take the left over corners of the reinforcement mat and add those slowly by adding them from the centre into concrete pushing it to the outside corners of the mould again with only millimetres to spare. A bit of overlap of the reinforcing material is fine. Once done add more concrete to the centre and around. Help to even the layer with the spoon once almost covered a bit of slight shaking will release more air bubble and even out the concrete.

Set it aside, best on a fairly smooth and level surface, and wait for at least 2 hours but don't forget that can vary with your concrete mix.

In any case time for a well deserved break!

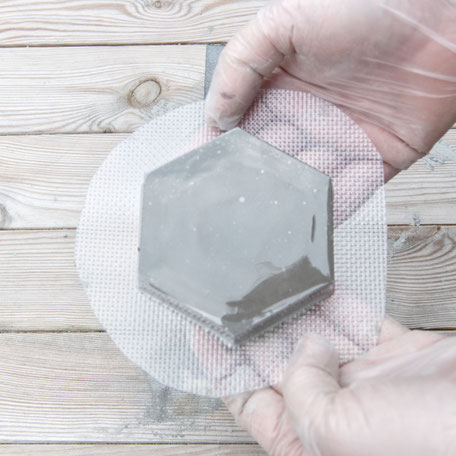

These gaps will bring air between the concrete and the mould which will allow it to gently release the concrete coaster. Below, you can see how the first gap gives air to the lower corner but you will feel at that stage more air is needed so keep doing what you do ....

Note - to avoid scratches inside the mould - don't mix inside the mould; wait until the concrete is fully surrounded with air to release the solid; remove left bits of concrete with a fine brush.

All cured and hardened the concrete on the left is just about ready to get out of the mould. I have to admit my break was bit longer, I waited about 4 hours just so you know.

I think this mould is worth reusing and it will allow good results for about 4 to 6 coasters if handled right. If you like to do so start by gently pulling the edges of the mould until small gaps appear all around as shown below.

Tadaah!

From here on out, your coaster will need maybe another day to dry a bit more but don't worry you can already use it. However, maybe you want to add some cork or clear bumper feet if you are planning on using them on glass or fine wood tables.

If you wish to keep them as wonderful grey as they are you could go on and seal them with beeswax, carnauba wax or similar. It will protect the concrete just similar to wooden cutting boards are protected but it would need to be updated from time to time. I think I could do a tutorial on this too, let me know what you think?!

All done - moving on to a well deserved cheers!

I hope you enjoyed this post, happy crafting and don't forget questions, tips and so on can be added below,

best Antje

Sanding can be done but you don't have to. However, sometimes the top corner or concrete edge is not so nice and a fine sanding paper or block could just do the trick to smooth things out.

You might also like ...

Write a comment

Danny (Thursday, 02 July 2020 14:47)

Very cool! Congratulations �����